Our

Equipment

Flushby Probe

Flushby rigs are equipment used in cleaning and maintenance services in oil and gas wells. Theyare known for their robustness and efficiency, and are able to perform various services in several wells in a single day. Its mobility between wells and speed of assembly and disassembly allows for faster access in any type of locations, compared to heavier rigs.

The main services are well clearance, gravel cleaning, sand removal and other types of waste that can obstruct oil and gas production. In addition, it is also used in preventive maintenance services, such as: installation of filters and valves, performance of pressure tests, exchange of well fluid, installation or maintenance of insertable mechanical pump, the sitting and displacement of insertable pumps, pistons or rotors, t these in bottom pumps (BCP and BM), insertable or tubular, polished rod rock, rodcolumn scavenger tube, BCProtor rock, sealing heads and boxes, among others.

Some important features of a flushby probe include:

- Portability: Transporting a flushby probe is easier and fastercompared to other similar equipment.

- Maneuverability: the flushby rig is able to be maneuvered from within the well location with ease to perform the necessary work. This is due to its size and weight, which are significantly smaller than other equipment.

- Load capacity: the flushby probe is for hoisting, carrying work tools such as BOP, chave hydraulics, as well as carrying circulation fluid in the wells.

- Pumping system: The flushby probe has a pumping system to inject fluids into the well under pressure during maintenance, cleaning and repairs. In some cases, it is possible to perform acidification in wells.

- Control system: the flushby probe has a control system that allows you to monitor and control the pressure during the working process.

- Safety: The flushby probe is equipped with safety devices, such as emergency locks, to ensure the safety of the operation team and prevent accidents. There is also engine emergency stop mechanism in case of gas and blowout, manual BOP closure in case of hydraulic failure or emergency stop of the probe, safety valves for high pressures.

Advantages of a flushby probe

Some of the advantages of a flushby rig for onshore oil well work include:

- Saving time and money: The flushby rig is an efficient piece of equipment that allows you to perform a wide variety of maintenance, cleaning and repair work on an oil well in a short period of time. This reduces well downtime and, consequently, production costs.

- Flexibility: The flushby probe is a flexible tool that can be used in wells of different depths and diameters. In addition, it is able to perform a variety of rod jobs, including well cleaning.

- Safety: The flushby probe is designed to operate safely and has built-in safety features such as emergency locks, in-circulation pressure safety controls.

4. Risk reduction: The flushby rig can reduce risks associated with oil well work, such as exposure to hazardous chemicals and personal injury. Operating with fewer people, the risk of accident greatly decreases, in addition to the fact that it does not operate with elevated rod platform.

5. Improved productivity: The flushby probe can improve well productivity by removing paraffin deposits, scale and other debris that can affect production, as well as pump replacement and/or repair.

6. Energy efficiency: The flushby probe can increase the MTB (meantime between failure) of the well by removing obstructions and allowing the mechanical bottom pumping system to return to production.

7. Saving resources: flushby operates without the need for other peripheral equipment such as pump skid, tanks, generators, trailers, etc., plus the fact that it needs a smaller group of people than a completion probe to perform the services.

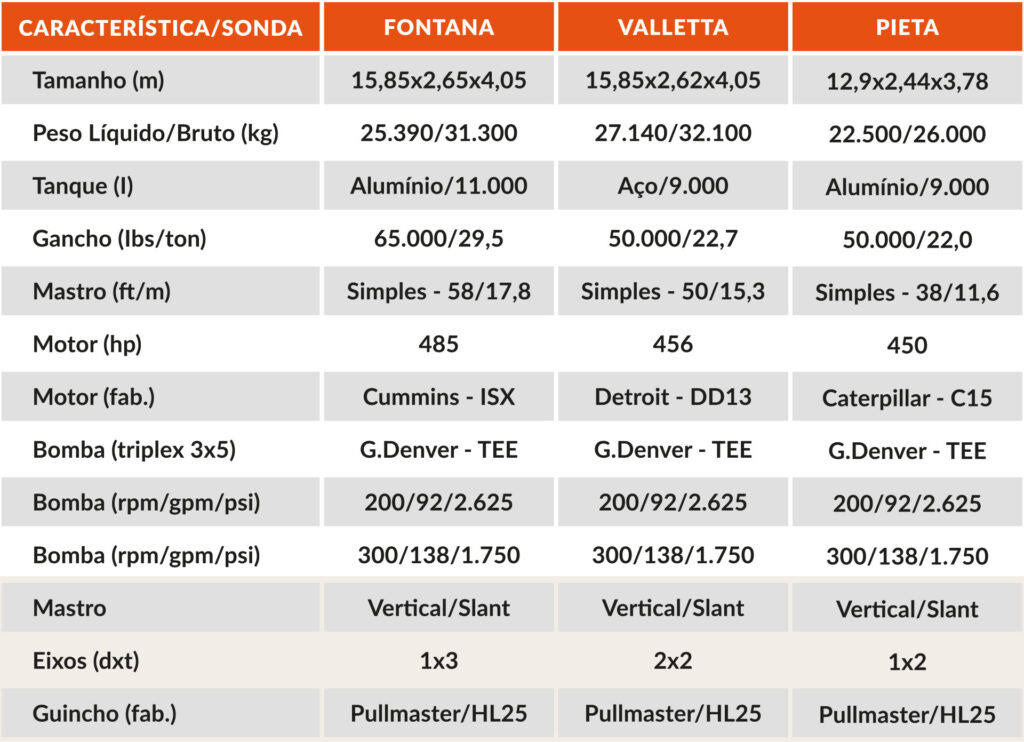

• Valletta is the newest and most robust probe of our squad with 4 axes and with storage and operation capacity of 9,000l, Fontana also has 4 axes and has more tank capacity with 11,000 liters

A • The Pieta is the smallest in size and lightest, but with the same load capacity.

• All work with pumping rods, have hydraulic key and BOP captive, has a circulation system with Gardner Denver triplex pump, with tank with up to 11,000l and manifold that allows various liquid transfer operations between the rig and well or with external water supply truck, incorporated into the probe. They are lighter, faster, and work without peripheral equipment, with fewer workers and are fast in the DTM.